Biden Jump-Starts Electric-Vehicle Push With Massive Lithium Loan

WASHINGTON—The Biden administration is providing a shot of energy into America’s flagging electric-vehicle industry.

Read moreAssets Under Management by Tanok Capital Partners LLC

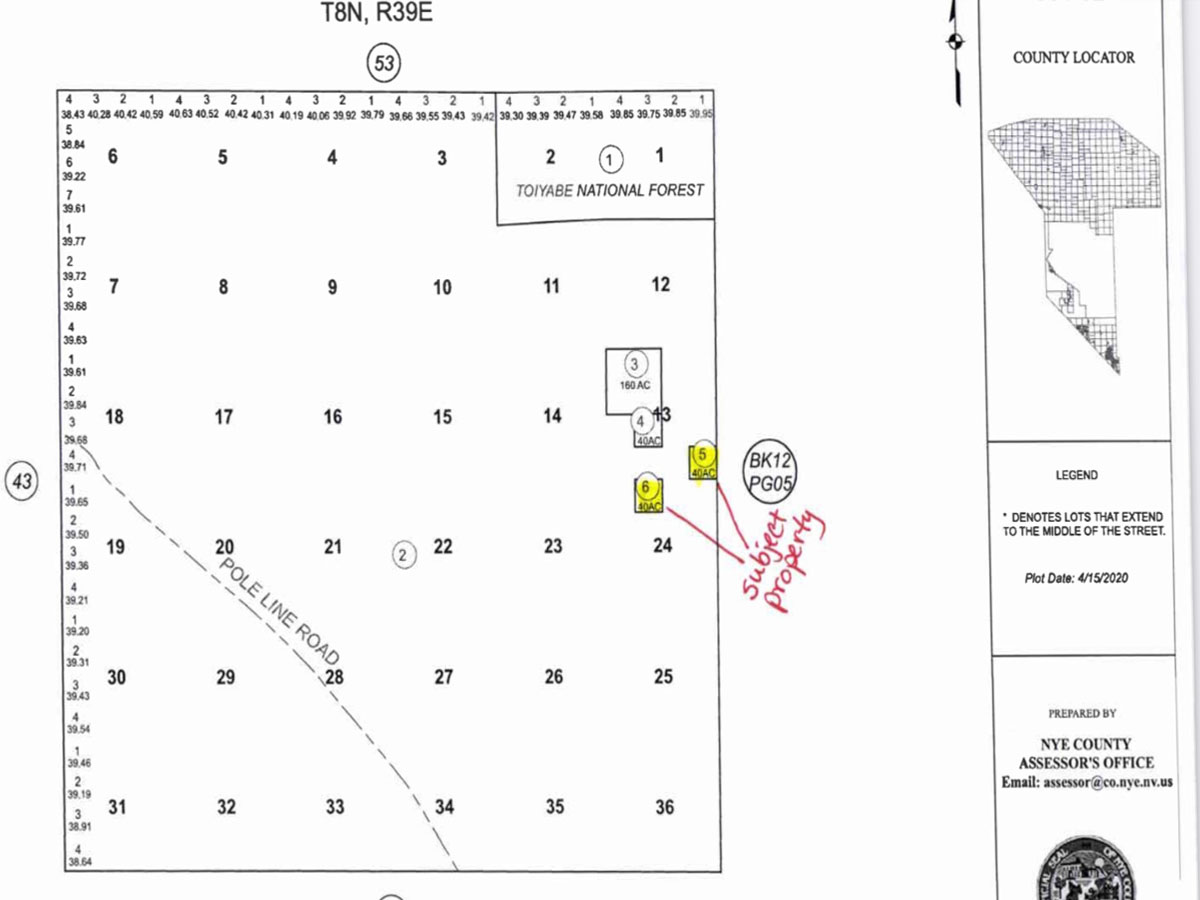

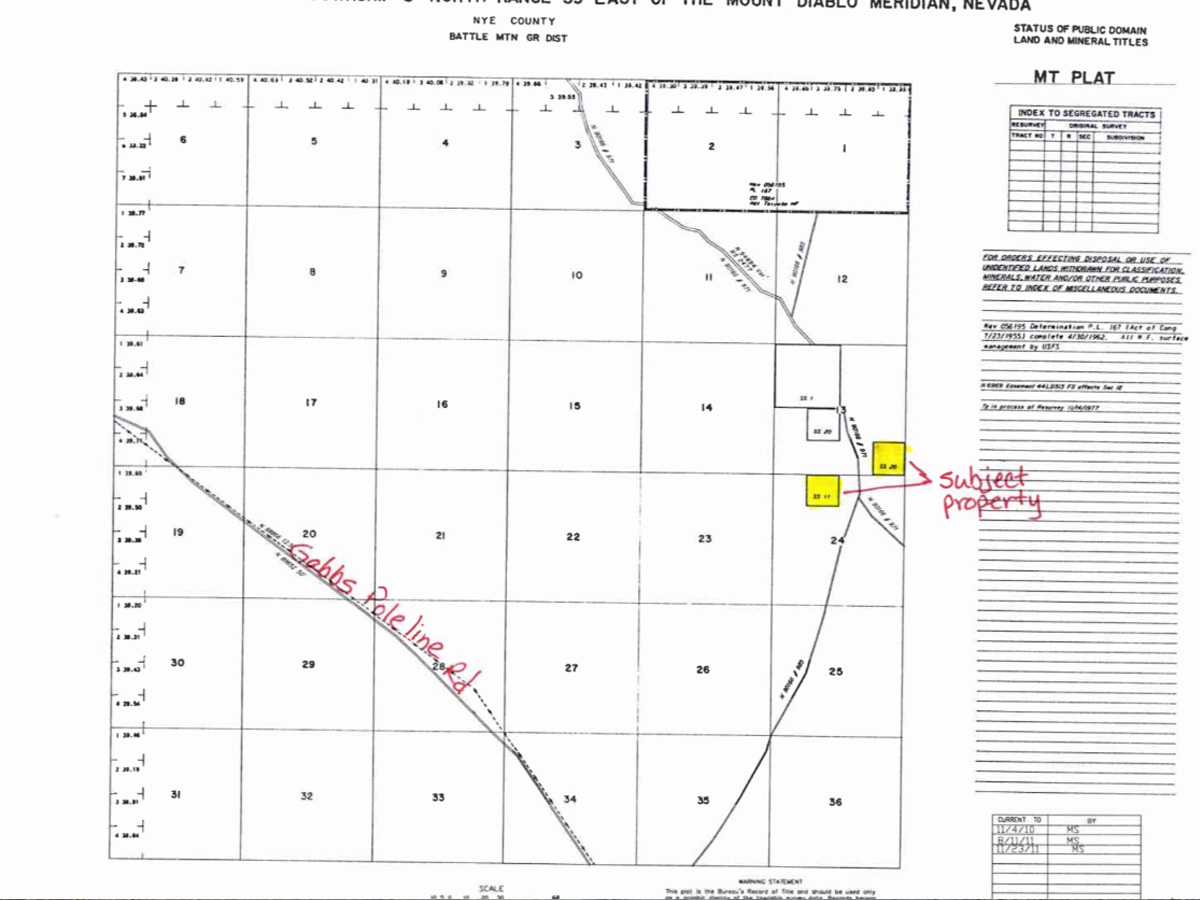

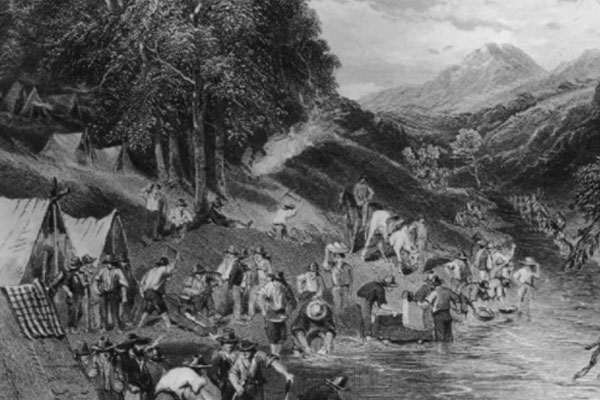

Cloverdale Mine encompasses 80 arces of privately owned deeded parcels of land. The land is mineral rich in vast quantities of rare earth elements, especially in Cerianite (Ce), Gold (Au), Scandium (Sc), Silver (Ag) and Palladium, there are other REE minerals such as Lithium, Neodymium and Dysprosium.

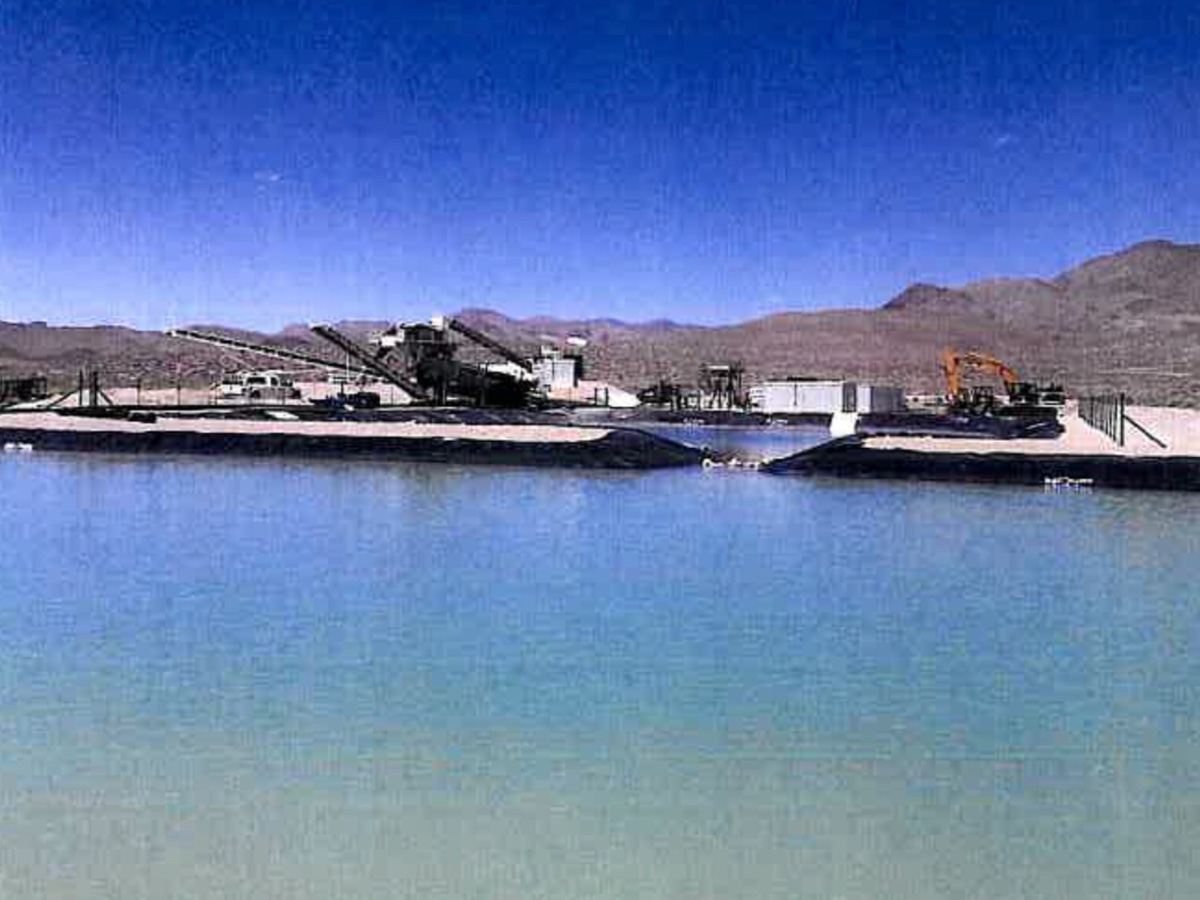

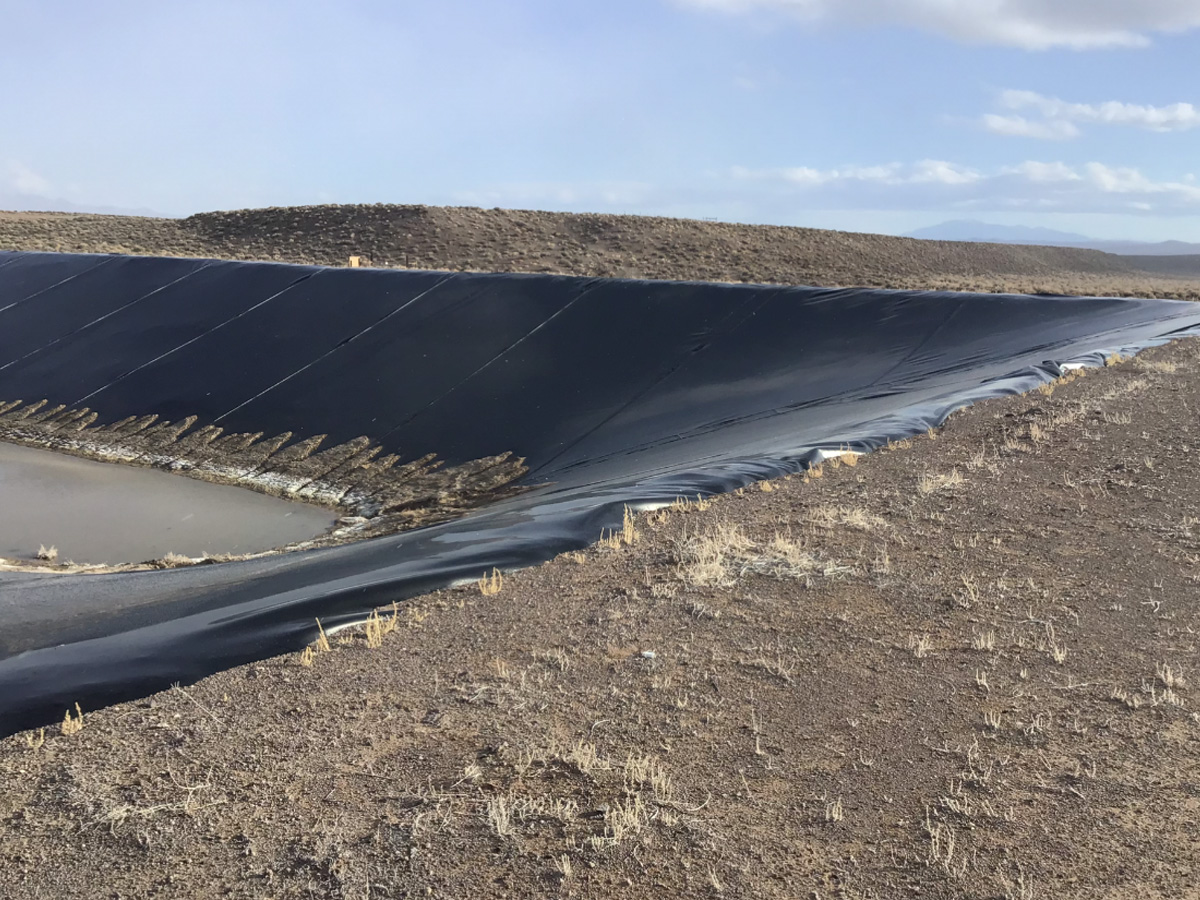

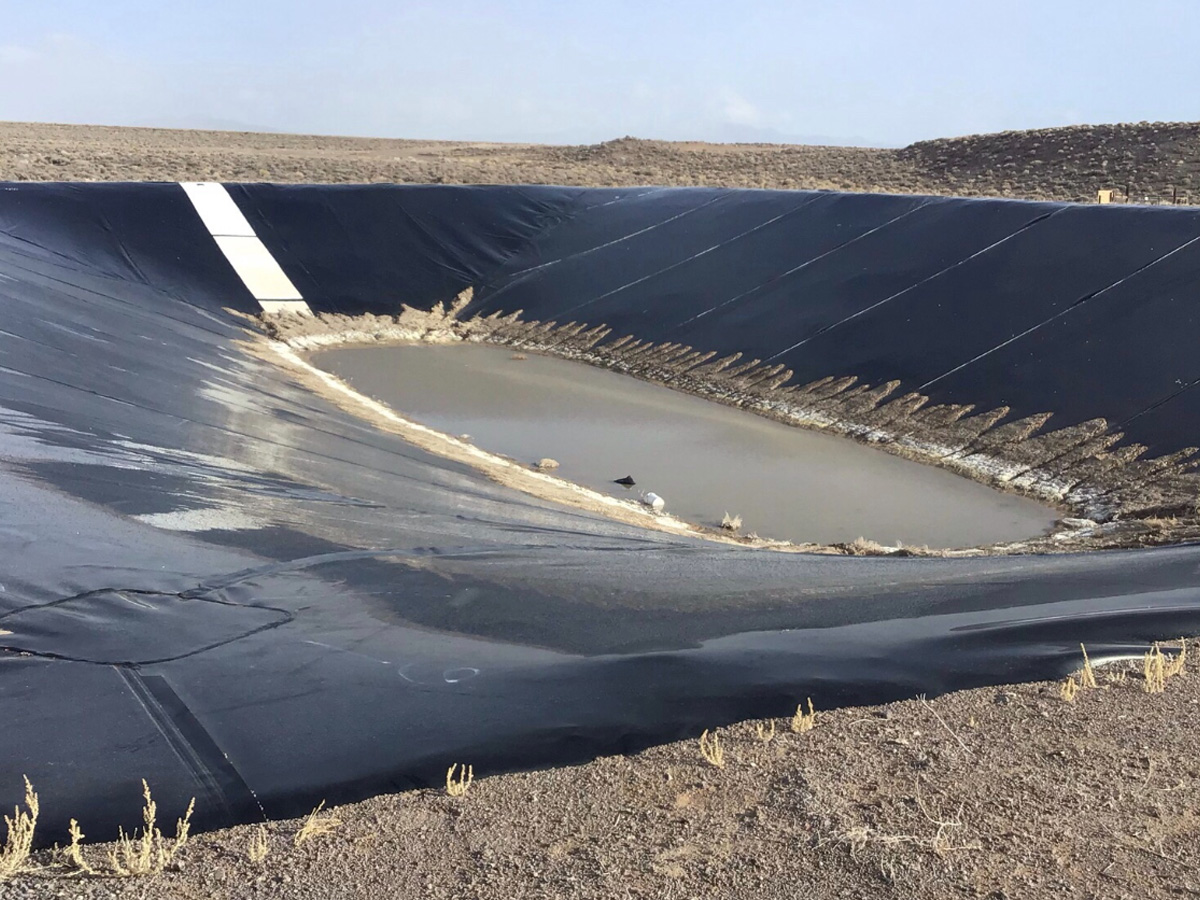

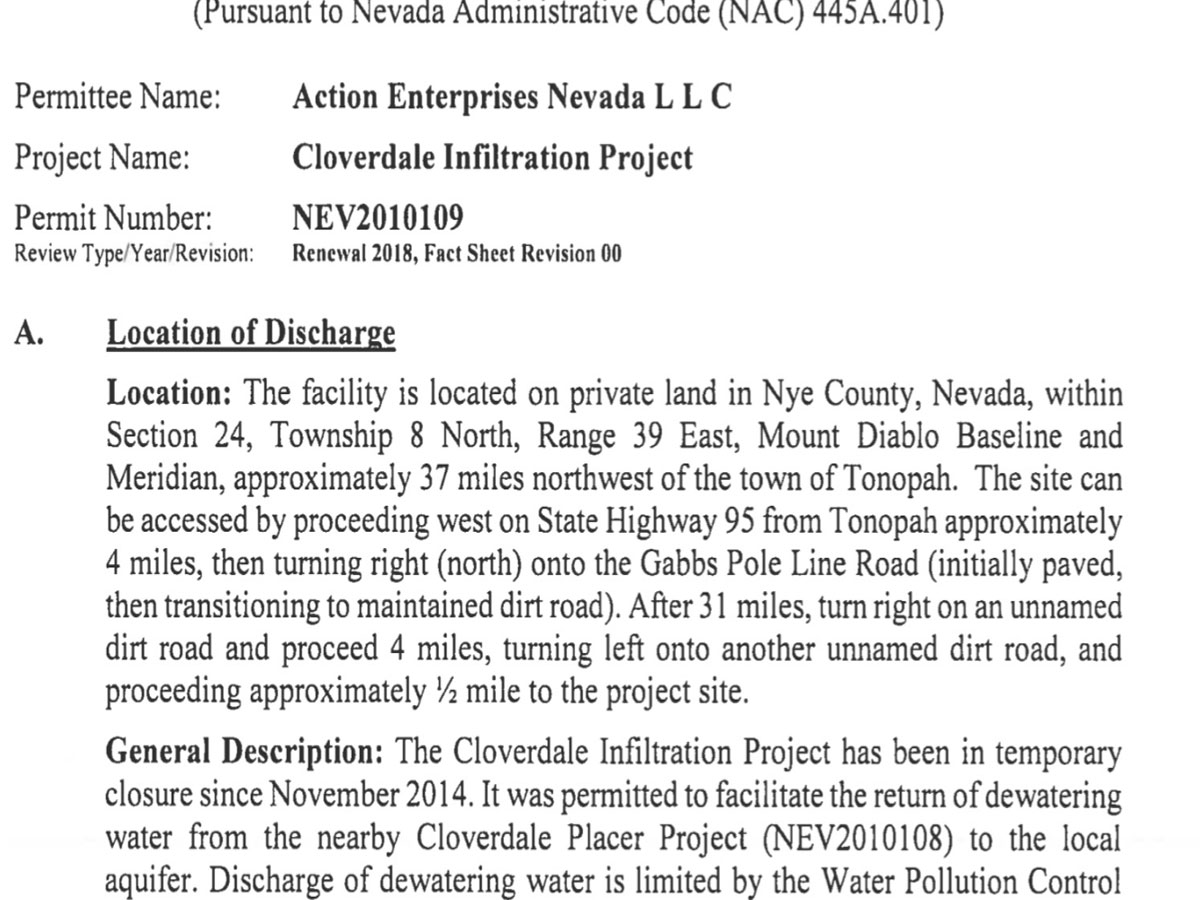

The property has ample water rights, permitted to discharge "up to 1,000,000 gallons per day, from dewatering pipes" (in NI 43-101 report), there are 20 acre feet of "deeded" water rights. The drought does not seem to affect this water supply. There were 4 monitoring wells which had been tested every 90 days, when plant was operating. This report is effective as of July 2018 (reviewed and update January 2023).

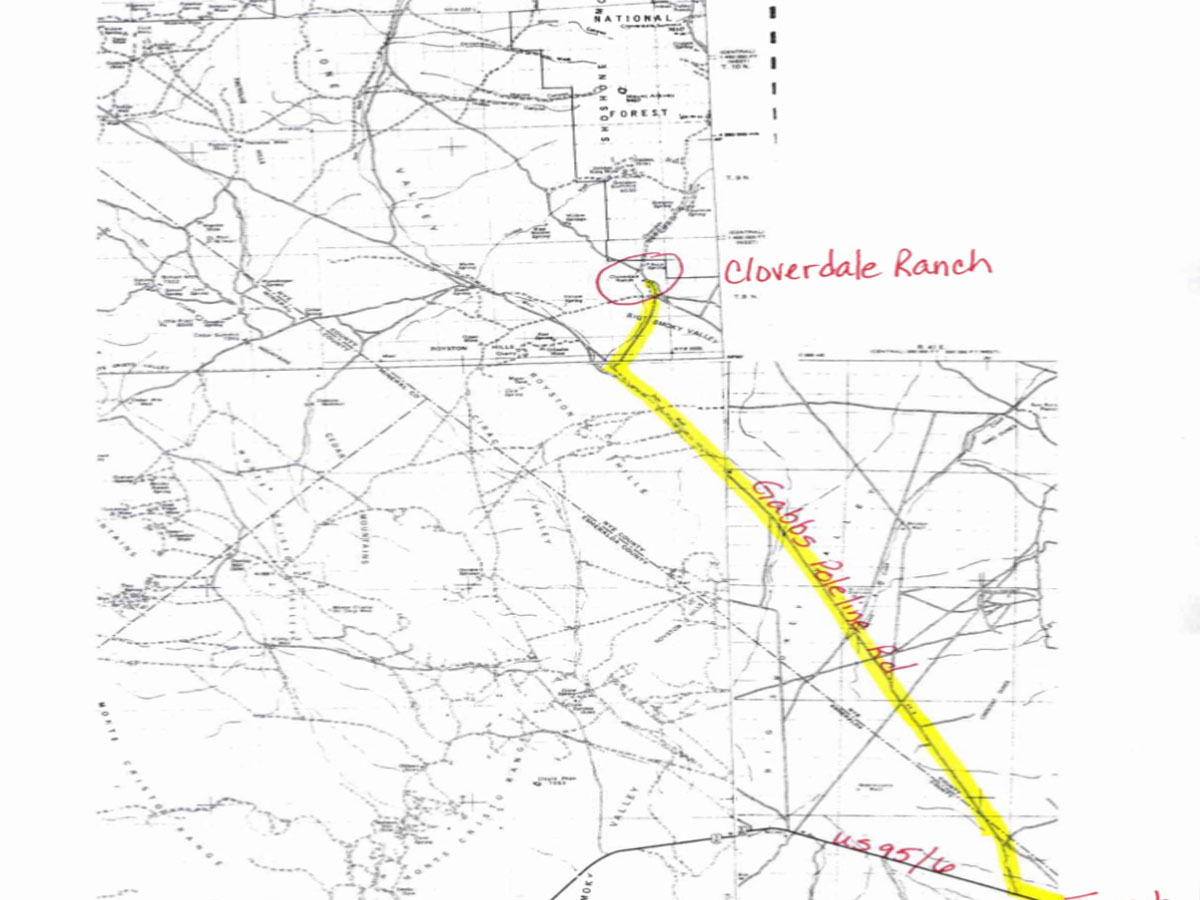

LOCATION: about 50 miles northwest of Tonopah, the county seat of Nye County. The Gold Flats alluvial fan covers about 50 square miles. Most of the ground is public domain, know as BLM (Bureau of land Management). Previously there were 10 160 acre claims on 1,600 plus BLM land. The mining operations stopped late November 2014, due to a seasonal shutdown. The plant ran long enough for testing of the ores and water flows. There are no liens on the deeded parcels.

OTHER MINES: Property is located within 30 miles of Manhatten mine and Round Mountain Mine. These mines have recovered over 20,000,000 Oz Au of Gold.

ASSAY REPORTS: were completed in 2009, on both the deeded 40 acres and 1,600 BLM land. (see attached ) Geological report has 3 assays and a 100 Ton, Bulk Sample results. These reports were completed for the Tom Funnery and Cloverdale claims. "Reports show a 100 Ton bulk sample, referenced in the geologist report, showing 4.48 troy oz. button recovered using Placer methods. Ralph Wilcox, JR, Geologist stated "..derived from one or more epithermal volcanic gold systems, has the potential to contain one million ounces of economically recoverable gold". Also in June of 2008, Ralph Wilcox Jr, Geologist, stated "in my conclusion.. then the target concept for Gold Flats is a Bajada (desert alluvial fan) placer deposit containing something on the order of one million ounces of economically recoverable gold" "Typically, in an ancient riverbed, Cloverdale Creek, the deeper gravels near bedrock yield higher ore values."

Separation Technologies include utilization or modification of currently available, commercial, physical separation systems (i.e., beneficiation via size, density, froth flotation, magnetic, ultrasound), hydrometallurgy and solvent extraction/digestion processes, and pyrometallurgy techniques (i.e., elec-tro-slag refining, acid roasting) to separate and concentrate REEs from coal-based resources such as coal, coal refuse, clay/sandstone over/under-burden materials, aqueous effluents, acid mine drainage sludge, and power generation ash. Advanced or new transformational REE separation concepts such as physical, chemical, electrical and thermal extraction, acid/base leaching, and ion exchange; reactive grinding, photochemical, ultrasonic-assisted, micro-wave-aided, photophoretic, plasma, and supercritical CO2 separation; as well as advanced sorbents and membrane systems, are being considered to further enhance REE separation. Researchers at West Virginia University (WVU) Research Corporation, aided by its partnership with West Virginia Department of Environmental Protection and supported by the National Energy Technologies Laboratory (NETL) have been working on how to separate REEs while cleaning up the acid mine drainage (AMD) from abandoned coal mines.

Plasma, which is distinct from the liquid, gaseous and solid states of matier, is formed by striking a gas with enough energy that gas molecules are ionized. During the past century, thermal plasma treatment saw applications in torch welding/cuting, spray coating, metal synthesis, extractive metallurgy, refining metallurgy, hazardous waste destruction and more. The collaborators researched using low-temperature plasma to pretreat coal-based materials resourced from West Kentucky No. 13 and Fire Clay mines located within the state of Kentucky. Surface area measurements found that plasma treatment provided increased surface area and pore volume which made other process- es more effective at recovering REEs. This novel technology integrated with traditional leaching and extraction processes was demonstrated to effectively recover REEs from the coal samples. Low temperature plasma treatment was found to provide heavy REE leaching performance improvements on the low-density, higher carbon content fractions of the West Kentucky No. 13 coal, and high-temperature oxidation provided exceptionally high REE recovery for all fractions of both the Fire Clay and West Kentucky No. 13 coarse refuse materials.

Ion Exchange involves rinsing the coal with a special solution that releases the REEs bound to it, which is more environmentally friendly and less demanding in terms of energy use than methods explored in the past. In a NETL-supported project with Virginia Tech, researchers developed a process leveraging simple ion-exchange leaching techniques currently used by industry. Quite simply, ions exchange places with one another, and thus different types of materials can be separated. “Essentially, REEs are sticking to the surface of molecules found in coal, and we use a special solution to pluck them out,” said Pisupati. “We experimented with many solvents to find one that is both inexpensive and environmentally friendly.” Ammonium sulphate was found to be the most effective solvent, but there are many more tests to come. According to the group’s work published in Metallurgical and Materials Transactions, they were able to extract 0.5 percent of REEs in their preliminary study using a basic ion exchange method in the lab. They are confident that they can increase the recovery to 2 percent through advanced ion exchange methods.

The $13 billion global rare earth market is growing at 10.8% per annum according to Global Market Insight Inc., as demand for electric vehicles, cellphones and other products rise. Since 1988, China has been the dominant supplier of REEs. In 2011, China provided 95% of the global market and decided to restrict exports and favor its own domestic industries—a decision that resulted in REE price volatility. Consequently, rising concern among industrialized nations has revitalized global interest in REE mineral exploration and extraction. Worldwide, several new commercial REE projects, in various stages of planning and development, are focused on diversifying supply; however, new efforts to purify and refine REEs remain limited. In 2009, intensified interest in strategic materials culminated in discussions regarding our nation’s ability to secure reliable supplies of REEs and other strategic materials. Strategic materials were identified as critical for growing the U.S. green energy and electronics industries, as well as for specialty military applications. In response, DOE released the first Critical Materials Strategy in 2010, identifying ytirium (Y), neodymium (Nd), europium (Eu), terbium (Tb) and dysprosium (Dy) as critical REEs.

WASHINGTON—The Biden administration is providing a shot of energy into America’s flagging electric-vehicle industry.

Read more

The new U.S. plan to rival China and end cornering of market in rare earth metals

Read more

US military interests have aligned MP's rare earth mining activities with the geopolitical agenda. EVs - which are central to MP's thesis, are at an inflection point of exponential growth in the adoption S-Curve.

Read more8615 Freeport Parkway, Unit 170

Irving Texas, 75038